A, Microperforation and B, cross section of micro-perforation as

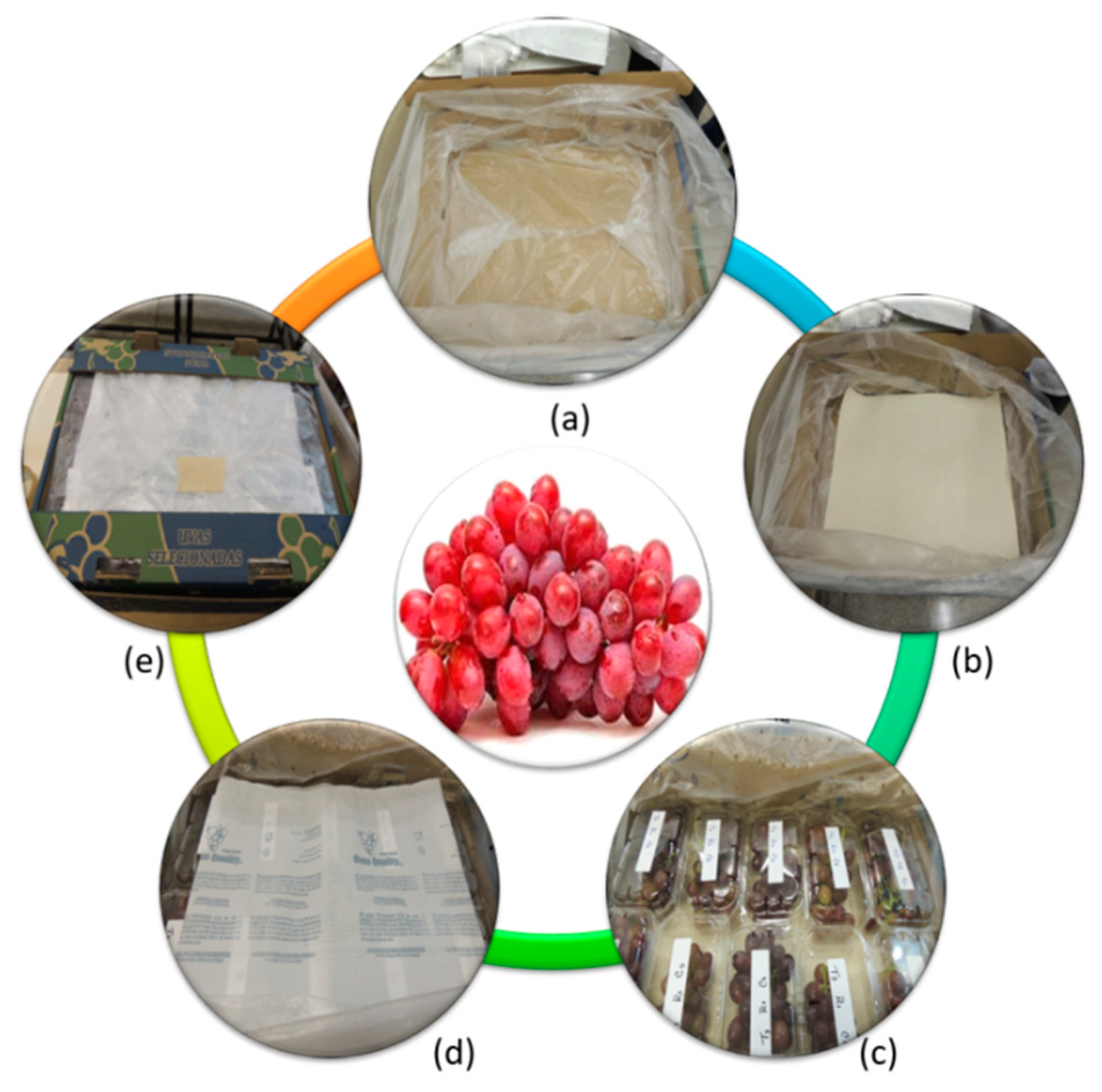

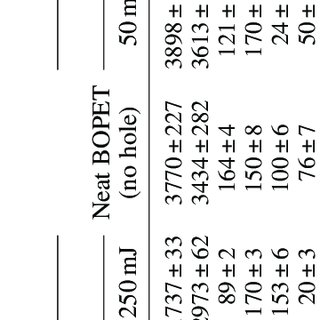

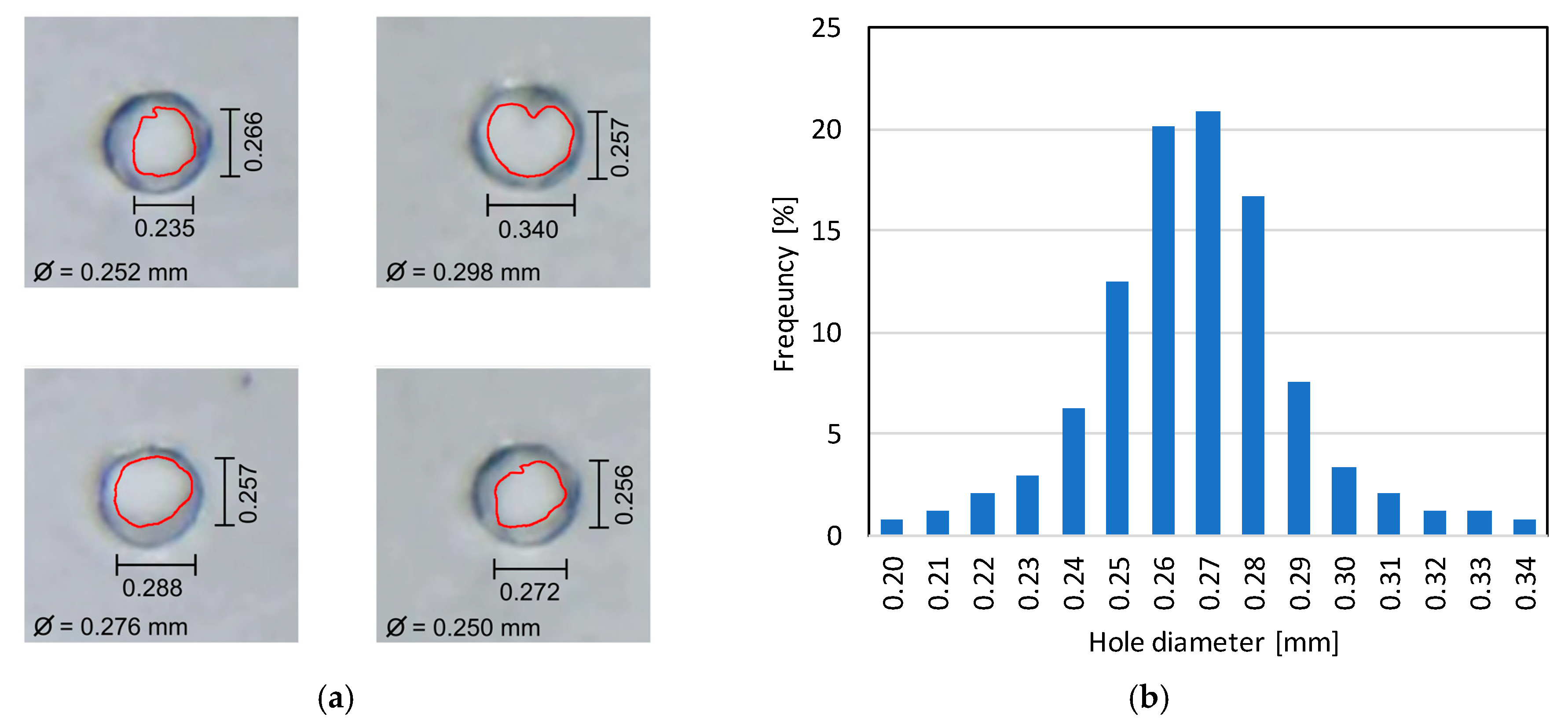

Download scientific diagram | A, Microperforation and B, cross section of micro-perforation as seen under SEM of BOPLA film with λ MD × λ TD of 4.0 × 4.0 perforated by CO 2 laser at fluence of 35.5 J/cm 2 from publication: Effect of biaxial-simultaneous stretching conditions on OTR and CO 2 permeation of CO 2 laser perforated poly(lactic acid) film | The biaxially oriented poly(lactic acid) films prepared using simultaneous biaxial stretching were perforated by CO2 laser with the power of 60 W. The focal spot diameter was fixed at 103 μm. Pulse durations were varied from 1 to 30 μs, which corresponds to the fluence from | Films, Motion Pictures as Topic and Film | ResearchGate, the professional network for scientists.

PDF] Low-frequency sound absorption of hybrid absorber based on

Takeshi KIKUTANI, Professor (Full), Doctor of Engineering, Tokyo Institute of Technology, Tokyo, TITech, Organic and Polymeric Materials Department

Research on sound absorption performance of ultra-thin metal micro

Applied Sciences, Free Full-Text

PDF] Low-frequency sound absorption of hybrid absorber based on

Acoustic behaviour of 3D printed bio-degradable micro-perforated

Takeshi KIKUTANI, Professor (Full), Doctor of Engineering, Tokyo Institute of Technology, Tokyo, TITech, Organic and Polymeric Materials Department

Acoustic behaviour of 3D printed bio-degradable micro-perforated

Witchuda DAUD, Researcher, National Metal and Materials Technology Center, Bangkok, MTEC, Polymer Research Unit

Charinee WINOTAPUN, Doctor of Philosophy, National Metal and Materials Technology Center, Bangkok, MTEC, Polymer Research Unit

Wannee CHINSIRIKUL, Executive Director

Wannee CHINSIRIKUL, Executive Director

PDF) Effect of biaxial-simultaneous stretching conditions on OTR and CO 2 permeation of CO 2 laser perforated poly(lactic acid) film

Charinee WINOTAPUN, Doctor of Philosophy, National Metal and Materials Technology Center, Bangkok, MTEC, Polymer Research Unit