Research on the integral forming process of thin walled and thick

Knockdown factor, κ, as a function of angular separation, φ (1,2) , for

Finite element model of the tensile test

Schematic of the toolpaths used in this work (8 passes are shown)

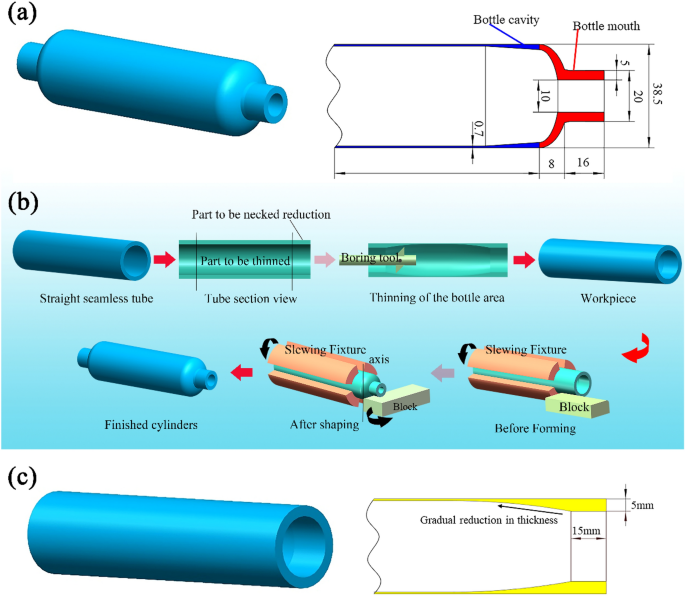

Research on the integral forming process of thin walled and thick mouth seamless gas cylinders

Illustration of deformed shape (shown is spinning pass 8) and the

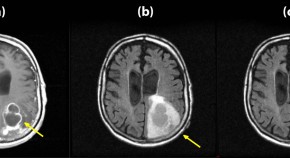

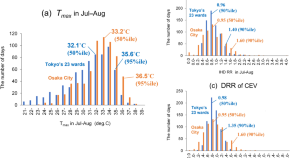

Browse Articles Scientific Reports

Curve of work hardening rate versus true stress at 1000 °C and 0.1 s −1 .

The desired 90⁰ pipe bend: (a) Geometry of pipe bend along with 10 mm

Influences of process parameters on defects and geometrical

Research articles Scientific Reports

Comparison of thickness changes in experiments and FE simulation after

PDF) Flow Forming : A Review of Research Methodologies, Prediction models and their Applications

a) Illustration of the three operations in the process. Load-stroke

Summary of experimental Design of Experiments approaches to flow forming.

Finite element study of stress and strain state during hot tube necking process - Hamed Zoghi, Alireza Fallahi Arezoodar, 2013