Reduce Moisture-Absorption and Cracking Risks With Seamless Wires - Hobart Brothers

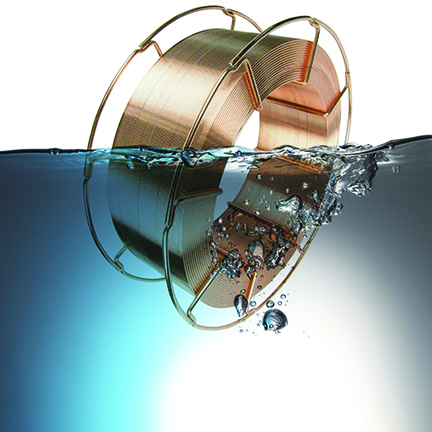

Reducing the opportunity for moisture pickup — in the filler metal and deposited weld metal — is important in any welding operation, but especially in industries with more critical applications.

Ultrasonic Antifouling Systems » Nordkyn Design

(Chemist2U) North Hobart Pharmacy restaurant menu in North

ITW Welding Middle East على LinkedIn: Reduce Moisture-Absorption

Reduce Moisture-Absorption and Cracking Risks With Seamless Wires

DESIGN FOR DURABILITY: - Realview

PDF) Emerging SiC Applications beyond Power Electronic Devices

Welding for Oil & Gas: Core Filler Metals - Hobart Brothers

Mohammed Gouse Makandar on LinkedIn: Maxstar® 161 - Powerful

Seamless MEGAFIL Welding Wire - Hobart Brothers

Corrosion-fatigue crack growth behaviour of wire arc additively manufactured ER70S-6 steel parts in marine environments - ScienceDirect

Submerged Arc Welding Consumables

Mohammed Gouse Makandar on LinkedIn: Maxstar® 161 - Powerful

21 Mar 1925 - Advertising - Trove

Mohammed Gouse Makandar on LinkedIn: How Can a Total Welding