Coatings, Free Full-Text

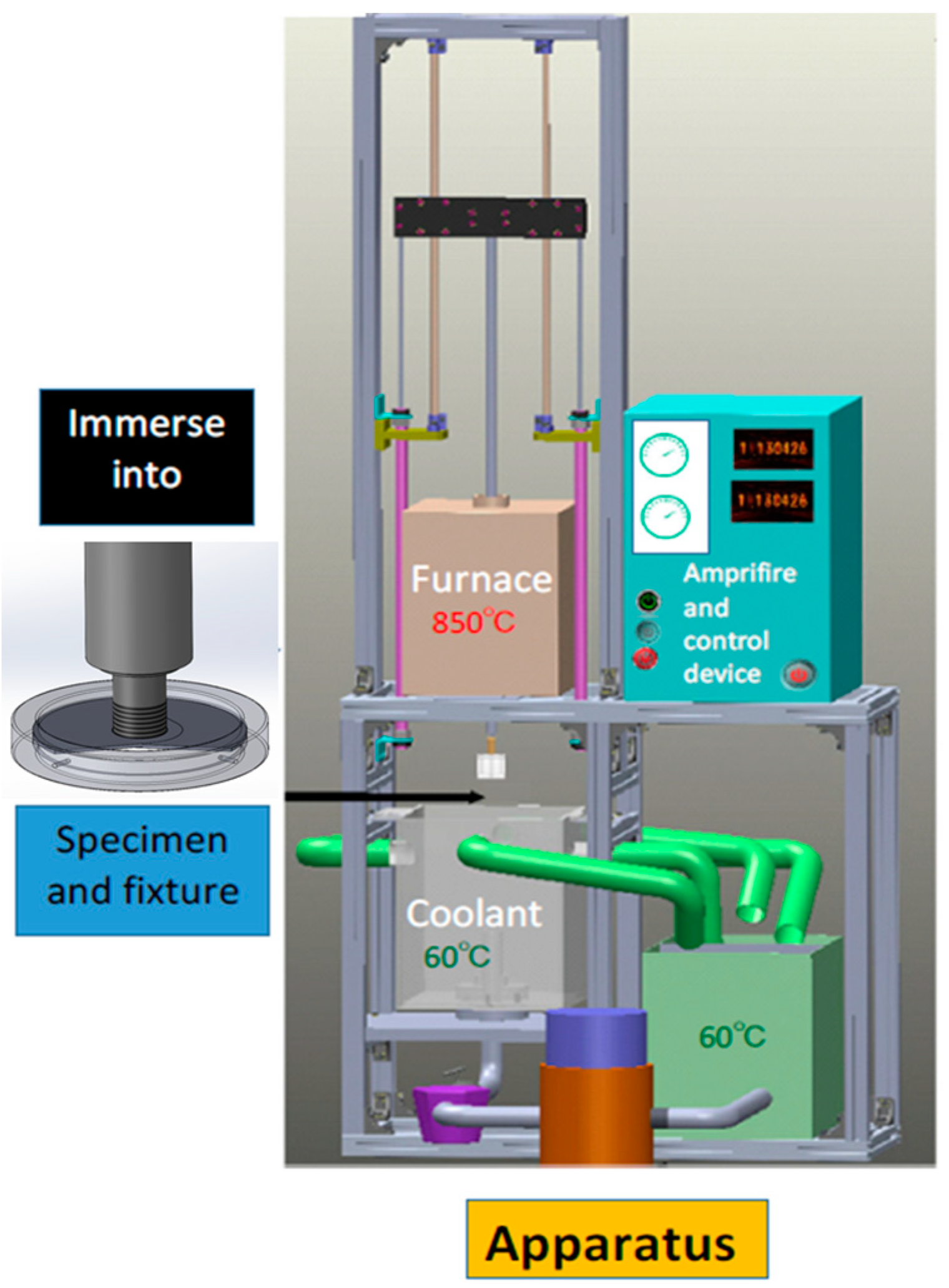

Inconel 718 alloy has a wide range of applications in the aerospace sector because of its superior mechanical properties and its weldability. The machining of such higher strength materials with complex shapes is possible with wire electrical discharge machining. In the present research, an endeavor was made to enhance the machining process by utilizing zinc-diffused coating brass wire electrode and Taguchi-Data Envelopment Analysis-based Ranking (DEAR) methodology in the process while machining Inconel 718 alloy. Material removal rate, kerf width, and surface roughness were considered as the quality measures. The optimal arrangement of input factors in the Wire Electrical Discharge Machining (WEDM) process were found as 140 µs (Ton), 50 µs (Toff), 60 V (SV), and 5 kg (WT) among the elected factors with the error accuracy of 1.1%. The pulse-off time has the most significance on formulating the quality measures owing to its importance on deionization in the process.

Types of powder coating paints

Coating-Composite and Functional Filter Material/Filter Rolls

Tribology of Diamond like carbon (DLC) coatings - About Tribology

Silicone 100% Pure Liquid Roof Coating

What does Solvent Free epoxy mean?!

Solved b) Rapidly cool to 625°C, hold for 1 s, then quench, c hold

Progress in Niobium Oxide-Containing Coatings for Biomedical, dr

Coatings, Free Full-Text

Epoxy FREE Tumblers & More with Diamond Finish Clear Coat

Catamount Coatings Premium Urethane 221 Clear Coat 7.5 Liter Kit

ASTM D2369-07 - Standard Test Method for Volatile Content of Coatings

Coatings, Free Full-Text, surf surf 1.101

MicrobeBlock Wall Epoxy: Antimicrobial Coating - Tri-Chem

Garage Floor coatings

Advantage Graphene Metal Roof Protection: The Eco Credentials